March 18 marks World Recycling Day. But what is recycling and, more importantly, is it the best way to make sure a product is sustainable?

The farmers of yesteryear used to say that out of a killed animal you don’t throw anything away, you have to find some manner to use everything. Back in the day, they were not concerned with excessive garbage creation, but rather with wastefulness. Today, we have to deal with both issues. In a more modern and elegant way we could say that recycling means turning a problem into a resource.

Is this the best way to address the topic of sustainability, one wondered? Not really, great would be for a product to be thought of from the beginning from a circular economy perspective: it is born by taking (perhaps renewable) resources from the environment and then returning them completely at the end of its life.

While this is considered the best way to be effective with one’s sustainable choices, it is true that crossing this finish line takes time and intermediate steps.

Freitag: an example of recycling

This is where the issue of recycling comes in, which we might recognize as a middle ground that attempts to do damage control.

Brands such as Freitag, which sensed as early as 31 years ago how important it could be to breathe new life into truck tarpaulins and vehicle seatbelts, soon became a style icon that would represent an entire generation for years to come.

His new line, for example, is the result of triple recycling:

the F670 WARREN shoulder bag, the F680 ANDERSON roll-up closure tote and the F690 COSTON backpack are made from a fabric made from recycled PET bottles, used tarps as well as reflective truck belts, and are designed in such a way that they can be repaired with ease.

Perfect for ensuring maximum visibility and thus safety even at night, on foot or on a bicycle, thanks to the reflective inserts.

A type of urban safety, we could call it, and certainly not comparable to the level that is claimed for work shoes, but safety nonetheless.

The evolution of safety footwear

And if those who have to buy safety footwear for their profession also want to pay attention to environmental issues and thus rely on products that propose a recycling idea, would they have any options to choose from? This is not a trivial question when one considers that by law, occupational footwear must fulfill several requirements and ensure performance up to par, while the often correct idea that a recycled material carries with it is one of diminished performance.

Exceptions to this are the two new products presented by Sixton Peak that will soon hit the market: the Helevo and Diventure.

A model from the new Sixton Peak line:

Helevo line

The Helevo line offers a lightweight yet durable shoe made from recycled materials. Starting with the sole, made from Ccycled® PU, a BASF product made from recycled plastics. “We believe we are the first in this sector to use this innovative technology developed by BASF, which provides top-quality recycled PU made exclusively from the recovery of waste, such as end-of-life tires,” they explain from the brand headed by the Maspica shoe factory.

The green soul of the Helevo line is also expressed in the upper, made of knitted fabric or digitex, both of which are recycled. To complete the model, a fiberglass toe cap with carbon nanotube reinforcements, a footbed that incorporates the D3O® insert that absorbs and dissipates energy, and finally the anti-puncture plate to protect against 3 mm nails, as per the latest regulations in force.

Diventure line

Also interesting is the Diventure line, designed specifically for working in high-risk outdoor environments. Also crucial here is the new robust PU/PU sole, again made from BASF polyurethane obtained from non-fossil sources, which ensures high slip resistance and ladder grip.

Innovations in the safety footwear industry

That the world of safety footwear is evolving considerably and is also facing the horizon of environmental protection is also evident from the technological innovations recently proposed in this regard.

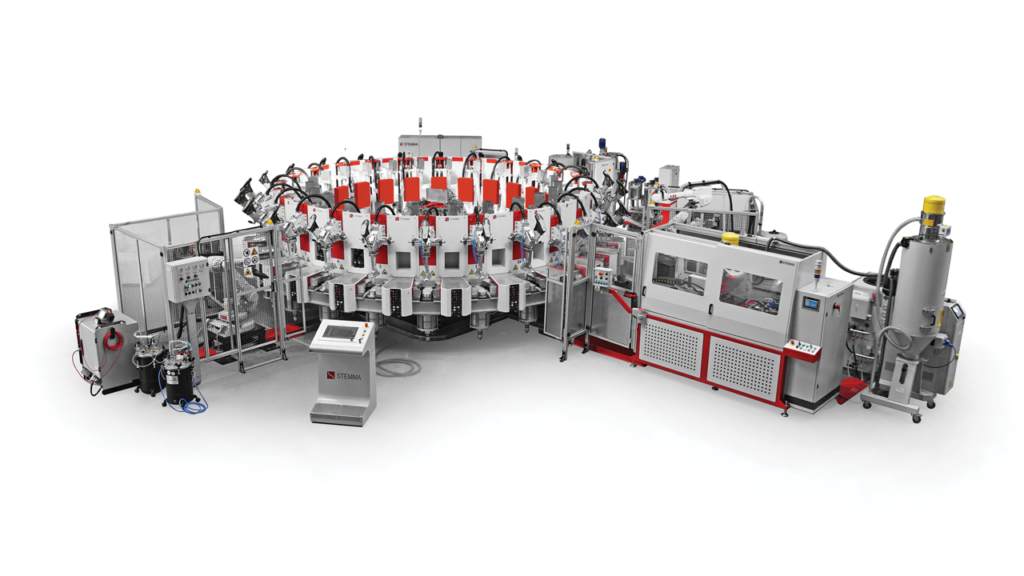

It is not necessary to know the technical innovations if you want to buy a responsible safety shoe, but it may be curious and still open your eyes to future prospects to know that an Italian company such as Stemma has invested heavily in research to propose to the world of production the “RE-YU” solution, the technology of recycling polyurethane waste from the molding processes of thermosetting polyurethane soles.

This technology allows about 15% of material recovered from production waste to be reused in the production of new soles, while keeping product weight, performance and comfort virtually unchanged. The mechanical pulverization system developed by Stemma stands out, from what has been available on the market so far, for the low cost of the process and the homogeneity of the powder obtained.

This upstream research thrust in finding solutions that are not only in line with the issue but also easy to implement and cost-conscious will be crucial.

You may also be interested in the following articles:

La Sportiva: the brand that embraces the challenges of nature

To best challenge the obstacles in running in nature, you need ad hoc technical equipment… and that’s where La Sportiva comes in.

Mountains shoes: how to face winter!

The mountains in winter can be a difficult and treacherous place for many, but not for everyone. We know a few working realities that find themselves spending a lot of time among the snowy peaks managing to work safely and comfortably with the right mountains shoes

Fast & Light: the new challenge of the mountaineering world

With Nadir Maguet, let’s discover the Fast & Light spirit for speeding over mountain passes.