When buying shoes, people very frequently look at everything except the sole. However, the type of material used, the fastening system between the sole and the upper, the tread pattern and the total thickness can say a lot about the type of shoe you are buying.

There are different types of soles for different types of shoes. Dress shoes, dancing shoes, running shoes or shoes for winter outdoor activities. The main choices are:

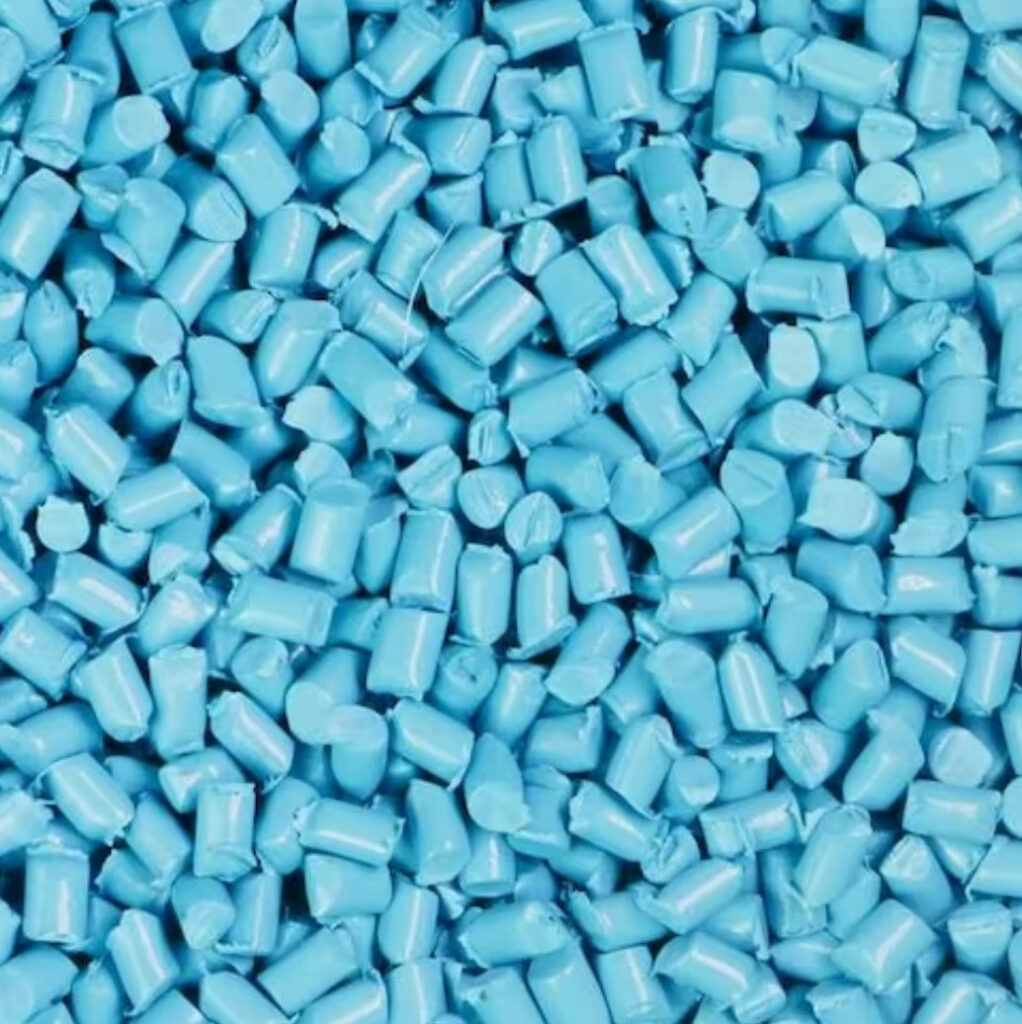

Thermoplastic rubber

When one thinks of shoe sole material, one immediately thinks of thermoplastic rubber. The most important ingredient is the famous styrene-butadiene-styrene, SBS, to which, to improve performance, other substances such as mineral fillers, antioxidants, pigments and oils are added from time to time, depending on use and manufacturer. Thermoplastic rubber soles are ideal, for example, for winter footwear, as they guarantee good performance even at extremely low temperatures.

PVC

To the uninitiated, it sounds strange, but it is true: PVC, or vinyl chloride, is often used for the production of soles. It would be surprising, in fact, to discover how many boots and sandals have PVC soles. Over the last few years, this material has been gradually perfected and its strengths have really increased.

EVA

Have you ever heard of the compound between vinyl acetate and ethylene? EVA takes the best of both materials to produce lightweight, highly elastic soles with good resistance to deformation.

Polyurethane

Polyurethane is used in two forms for the production of shoe soles: thermoplastic polyurethane is popular for the production of sports, safety and leisure shoes; two-component polyurethane, as the name suggests, is used in liquid form and is composed of isocyanate and polyol.

It is therefore necessary, as always, to find the right balance to make the most suitable choice for our needs.

You may also be interested in the following articles:

Ecoalf: advanced technology for sustainable footwear production

How Ecoalf makes stylish and durable shoes with environmentally friendly technologies wages

Soles (and shoes) are not all the same

By learning to distinguish the differences and characteristics among different soles, it can help you choose the right shoes.

The passion for shoes, evolving like technology

Shoes, technology and passion. The world of footwear, trends and latest evolutions.